Liquid Oxygen Bottle

The structure of the Dewar flask

The inner tank and outer shell of the Dewar are made of stainless steel, and the inner tank support system is made of stainless steel to improve strength and effectively reduce heat loss. There is a thermal insulation layer between the inner tank and the outer shell. Multi-layer thermal insulation materials and high vacuum ensure the liquid storage time.

A built-in vaporizer is arranged inside the shell to convert cryogenic liquid into gas, and the built-in supercharger can increase the pressure to a predetermined pressure and keep it stable during use, achieving the purpose of rapid and stable use. Each insulated gas cylinder has a stainless steel ring structure (protection ring) to protect the pipeline. The protective ring is connected to the cylinder with four brackets, and each bracket is slotted to facilitate the use of trolleys and cranes to carry the gas cylinder.

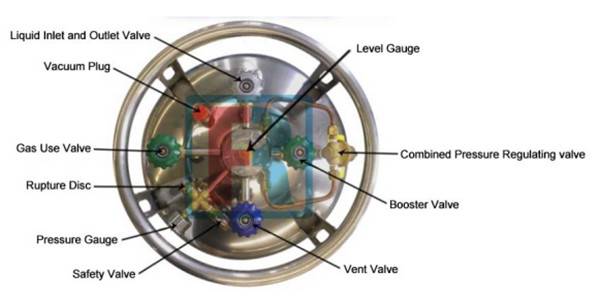

All operating parts are placed on the top of the gas cylinder for easy operation. In an independent use environment, the user can effectively control the use process through the discharge valve, booster valve, pressure gauge, liquid phase valve, etc.

In order to ensure that the inner liner of the gas cylinder is below the safety pressure, a safety valve and a rupture disk are installed on the gas cylinder.

Uses and characteristics of Dewar flasks

It is used to transport and store cryogenic liquids such as liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, LNG, etc. The gas cylinder can be used to supply liquid or gaseous gas.

The gas cylinder is easy to use, safe and reliable, economical and durable. The specific features are as follows

1. The support system of the inner tank is made of stainless steel to achieve the purpose of low heat loss and high strength.

2. It is easy to use and can be operated independently by a single person.

3. Store pure cryogenic liquid. Large storage capacity. The gas storage capacity of a DP175 dewar cylinder is equivalent to more than 18 times the gas storage capacity of a standard high-pressure gas cylinder.

4. The internal pressure of the gas cylinder will rise during the deactivation phase after filling. The gas cylinder has a high-performance insulation system, and its pressure rise rate is low. Under normal circumstances, there is no need to reduce the pressure through a safety valve.

5. The built-in supercharger and vaporizer can realize continuous supply of gas or liquid, and there is no need to install an external vaporizer under the designed dosage.

Application scenarios

Welding industry

Medical industry

Aquaculture industry

Gases subpackage industry

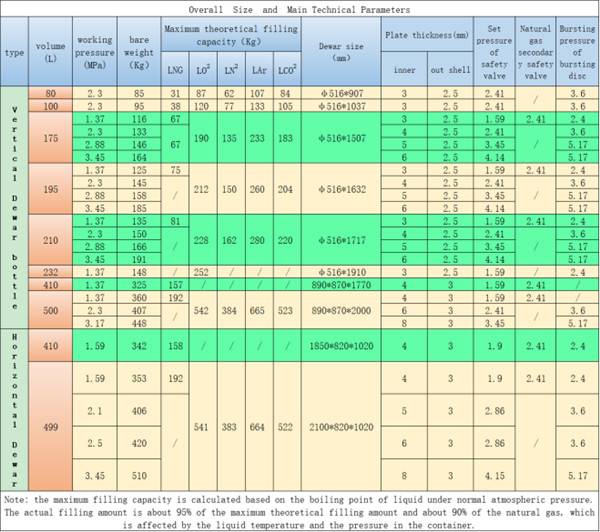

product data

Product details

Note: When filling natural gas, use double safety valves and eliminate the rupture disc in the inner tank.

Caution: Adjusting the top bolt of the combined pressure regulating valve will not have the effect of accelerating the pressurization speed. Adjusting the top bolt of the combined pressure regulating valve at will will result in combined pressure regulation. The valve is damaged.

Combined pressure regulating valve: This valve has the dual functions of pressure regulation and air saving. When pressurizing, the cryogenic liquid in the bottle is converted into saturated steam through the pressurizing coil, and then returns to the gas phase space at the top of the cylinder through this valve, thereby providing a continuous and stable pressure in the cylinder. When using gas, the gas with too high pressure in the gas phase space on the top of the gas cylinder is preferentially discharged to the outside through this valve to avoid gas loss caused by the opening of the safety valve due to excessive gas pressure. The solar term is automatic without manual operation.

Gas use valve: This valve is connected to a built-in vaporizer, through which vaporized gas can be obtained. It needs a CGA connector that matches the gas supplied by the container.

Inlet and outlet valve: This valve is used to control the filling and discharging of cryogenic liquid. The user can connect to the CGA pipe joint in front of the valve through a special hose , Carry out the filling and discharge of gas cylinders.

Boosting valve: This valve controls the built-in booster circuit. Open this valve to pressurize the bottle.

Drain valve: This valve is connected to the gas phase space of the gas cylinder. Opening this valve can release the gas in the cylinder and reduce the pressure.

Pressure gauge: Displays the pressure of the gas cylinder, the unit is pounds per square inch (psi) or megapascals (MPa).

Level gauge: The cylinder level gauge is a floating rod spring type level gauge, which uses the buoyancy of the cryogenic liquid to approximately indicate the cryogenic liquid in the cylinder Capacity. But accurate measurement must be weighed.

Safety device: The cylinder liner is designed with a first-level safety valve and a second-level rupture disc to protect the cylinder when overpressure. (In the case of overpressure) the safety valve is opened, and its function is to release the pressure rise caused by the normal heat leakage loss of the insulation layer and support, or the pressure rise caused by the accelerated heat leakage after the vacuum of the sandwich layer is broken and under fire conditions. When the safety valve fails, the bursting disc will open to release the pressure to ensure the safety of the gas cylinder.

Note: When filling natural gas, use double safety valves and eliminate the rupture disc in the inner tank. The protection of the enclosure under overpressure conditions is achieved by a vacuum plug. If the inner tank leaks (resulting in excessively high interlayer pressure), the vacuum plug will open to release the pressure. In case the vacuum plug leaks, it will lead to the destruction of the interlayer vacuum. At this time, “sweating” and frosting of the shell can be found. Of course, frost or condensation at the end of the pipe connected to the bottle body is normal.

Warning: It is strictly forbidden to pull out the vacuum plug under any circumstances.

Note: Rupture discs can only be used once. The rupture disc must be replaced after it has acted. Can be purchased from our company.